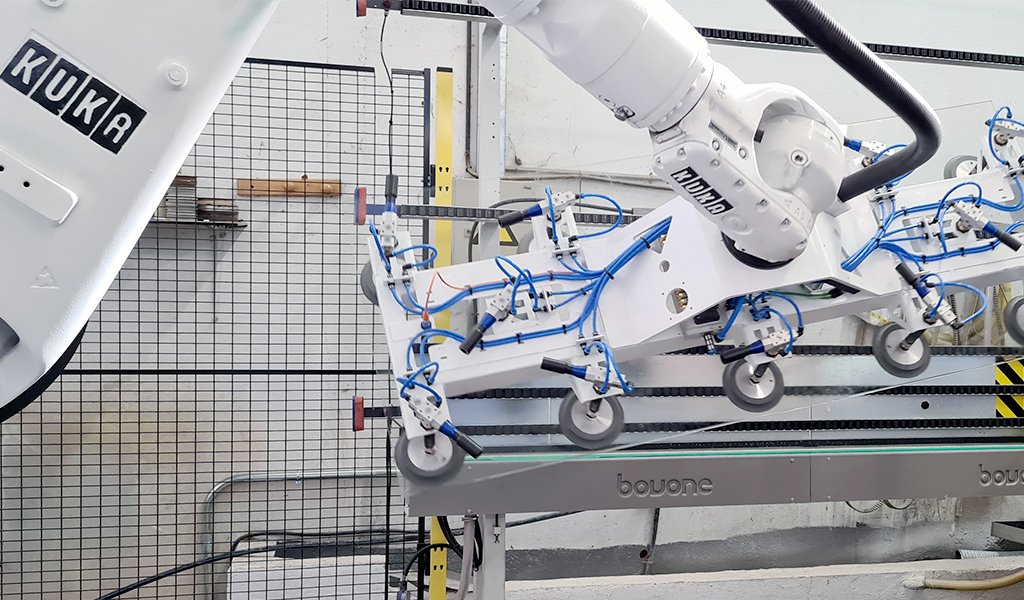

Automation in SMEs. The future of robotics is for everyone

For decades, industrial automation has been exclusive to large companies, making it difficult for SMEs to compete in the industry. As a result, they were forced to work in their factories in a more manual way with a heavy physical workload on their employees.

This situation has evolved over time and technology has been developed that is accessible to all, allowing the automation of processes in small companies.

Is automation hurting jobs?

The consequences of industrial automation are controversial and we find different opinions about it. On the other hand, as this technology has been evolving in industries, we can see a positive change in companies.

The automation of industrial processes comes to make the day-to-day lives of workers easier and safer, leading them to higher-value jobs.

With the advent of new technologies, 52% of current jobs will be lost, according to Randstad. In contrast, the World Economic Forum predicts that 133 million new jobs will be created.

On our website you can consult the opinions of our customers after acquiring a robot to automate their production lines.

How do robots help in warehouses?

In a warehouse we can find all kinds of robots working in many sectors, such as food or automotive. In this way, production is significantly increased, improving the final result. In addition, robots make the working environment safer and more pleasant.

Types of robots in warehouses:

- Case or bag palletizers

- Glass or panel manipulators

- Automatic guided vehicles

- Automatic shrink wrappers

- Pick & Place (high speed packaging)

For an affordable price you can now automate an entire production line, which means a great growth opportunity for all small and medium-sized companies.

If you wish to know more details you can make any inquiry from here.