Robot Pick and Place, high speed packaging system

PACKS BY PICKING UP TO 100 PRODUCTS PER MINUTE

Atlas Robots' high-speed Pick and Place packaging system allows the identification, grip and placement of up to 100 products per minutewith a cadence of up to 6000 references per hour.

The flexibility of the system allows the packaging of many different productsThe only thing you have to do is to select the production through the HMI control system and, instantly, the new configuration will be ready to work.

The artificial vision integrated in the system allows, in addition to detecting the exact position of the product, calibration and quality control.

Watch it on video

See how our high-speed packaging robot works

Pick and place of another level

Introducing our Pick and place robot for high speed packaging. With our solution you will be able to pack up to 100 products per minute simply by pressing a button.

And how? Thanks to the system "click & Go"With the integrated screen, starting production or switching to a new one is as easy as a finger tap. You won't need specialized personnel or extra qualifications, anyone on staff can use it.

Characteristics of the pick and place robotic system

It packs up to 100 products per minute and changes production instantly.

Packaging of 100 products per minute

Ultra fast packaging of up to 6000 products per hour.

Valid for multiple productions

Instantaneously reconfigures to package any production.

Calibration and quality control

Artificial vision system that allows product recognition, calibration and quality.

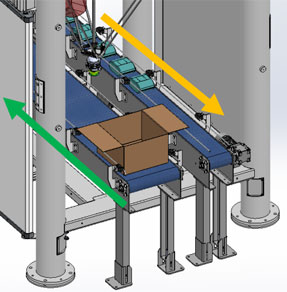

Operation of the pick and place robot

We explain the process of high speed packaging

01.

A conveyor belt introduce production in the room where the Robot is located to capture the product and place it according to the programming. Through a encoder installed on the belt and a machine vision system the robot is able to know the position of the incoming product at all times.

02.

Next to him is another group oncoming where the product will be left, ordered according to programming.

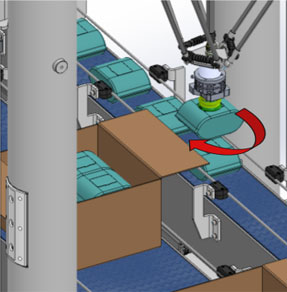

03.

The robot uses a Vacuum system installed in its jaws to capture the product and place it correctly on the adjacent band according to its programming.

04.

The product leaves the robot structure correctly positioned in its position inside the tray as programmed. These will be sent to the next production process.

Pick and place robotic system applications

We design, program and build pick and place facilities for the main meat and fruit and vegetable industries.

Know everything we can do for you

Robots that increase your company's productivity and improve your workers' quality of life

SPECIALIZED IN BRINGING IMPROVEMENTS TO MAJOR INDUSTRIES

AGV, automated guided vehicle

ROBOTIC PALLETIZER FOR ALL BOX AND TRAY PALLETS

The Autonomous Guided Vehicle AGV from Atlas Robots enables the driverless transport of pallets along a predefined route. Through the integrated software we plan the route and the system itself communicates with the rest of the robots to ensure the maximum picking and delivery rate on the pallets.

Automatic loading system during downtime

The system detects periods of inactivity and uses them to recharge the batteries..

Simple production changeover

At the touch of a button, you will be able to change the type of production without requiring skilled personnel.